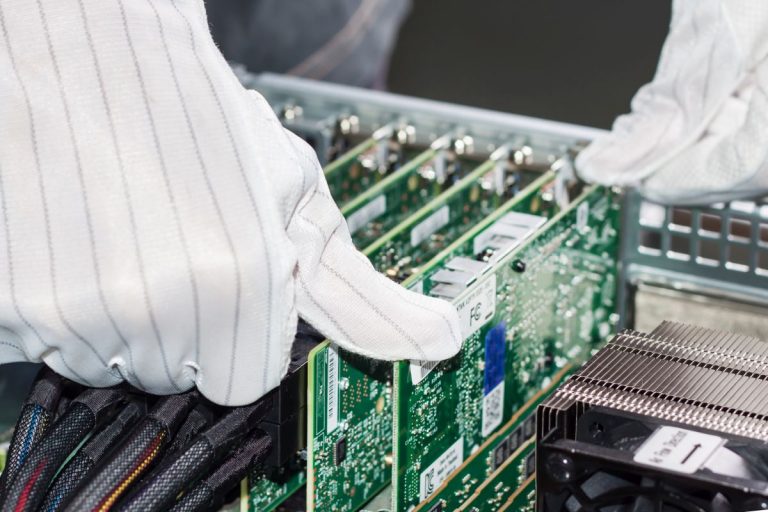

Building Server in an ESD protection zone (EPA) is a part of routine for Happyware Server Europe.

Electrostatic discharges are a source of error that should not be underestimated in high-quality server production. Happyware has successfully dealt with this issue since 1999. Comprehensive protection of all components used against electrostatic discharges is part of our ESD concept and therefore an important element in our quality assurance system.

To prevent your boards, CPUs and assemblies from being damaged, the entire production environment at Happyware is designed as an Electrostatic Protected Area (EPA). This means that the entire production environment is equipped with dissipative surfaces. This also applies to our warehouse, since ESD-compliant handling does not begin with the assembly.

Building server in an ESD environment requires extensive action

All our employees who are building servers or come into contact with server components, wear both ESD-compliant clothing and appropriate footwear. At the workstations, even higher safety regulations apply: the chairs are covered with static-dissipative fabric, and our employees wear “wrist-earthing” tapes, dissipative gloves, or, when tight, appropriate “fingerlets”.

Instead of using VDE-compliant protection-insulated equipment, we work with largely conductive tools which provide a potential equalization to the user and thus allow for a defined, slow charge balancing when touching assemblies.

In addition to these “normal” protective measures, we also pay attention to small things. For example, adhesive strips of packaging are not peeled, but are cut in general—one of many additional measures to avoid electrostatic charges.

In this way, all components are optimally protected and damage to the interior of the components is prevented. Finally, the finished servers leave the ESD protection zone exclusively in standard, prepared packaging or in a corresponding transport container.

Building Server in an ESD-protected environment is part of our quality assurance measures

All these measures are to ensure the quality of our assembling process. ESD damage often occurs with a time delay and would therefore not be noticed either in the device test or in our final quality control. The consequence of an ESD damage would therefore be a failure of the component after a certain runtime, usually when the server is already in a productive environment. Such a failure does not only cost the user time and stress but may also harm their finances. Consequently, it is our aim to reduce the chances of risks occurring.

Safety first – Happyware also offers extended, individual warranty services

Through the ESD safety rules are consistent and comprehensive, we can ensure maximum reliability of our systems. On this basis, we offer significantly extended warranty options for our customers. If our guarantee packages do not meet your expectations, we also offer individual guarantee solutions. This allows you to tailor the various Happyware warranty offerings precisely to your technological requirements and thus minimize your downtime.

Please also note the corresponding warranty conditions.

Happyware Server Europe GmbH is certified according to DIN ISO 9001: 2008 and DIN ISO 14001: 2015. Continuous quality management and top engineering services enjoy high priority.

Happyware – IT’s all you need!

Recent Blogs

New HPC / AI servers based on the AMD Instinct MI300 series

Posted onWith the MI300X Series, a new player has appeared on the GPU market that will reshuffle the cards in the AI sector. AMD Instinct™ MI300X…

We have moved – With our own new building, we are ready for the future

Posted onAfter nine months of construction, we were able to move into our new company building at the beginning of July. Our customers can now find…

Datacenter SSDs für den absoluten Performance-Boost

Posted onNoch keine Enterprise SSDs im Datacenter im Einsatz? Worauf warten Sie noch? Im Consumer Bereich haben SSDs längst Einzug gehalten. Und wer heute die Ladezeiten…